Technical

CORE OPTIONS

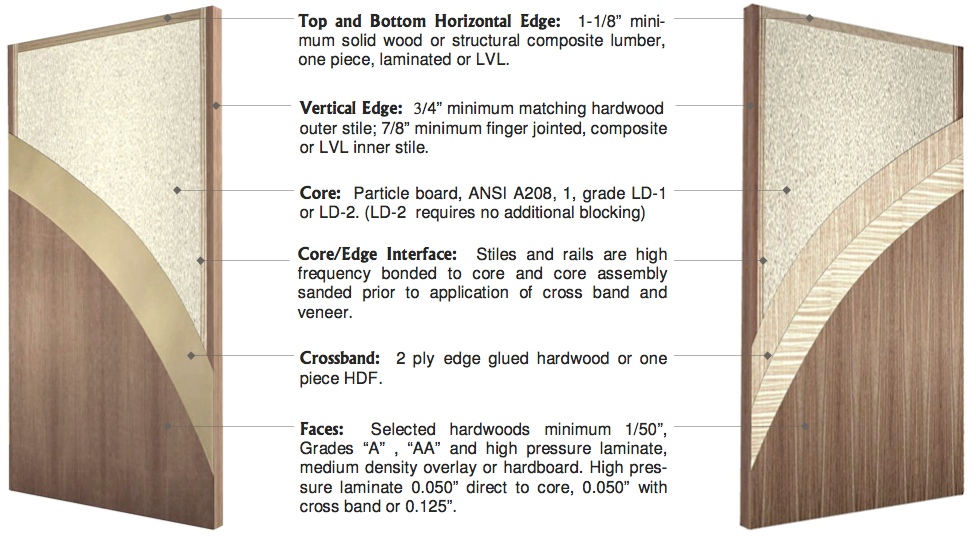

Particleboard

P-Series Particleboard Core 520P/530P

Top and Bottom Rail: 1-1/8” minimum solid wood or structural composite lumber

Vertical Stiles: ¾” thick matching hardwood stile for

wood veneer doors; mill option for paint grade doors

Core: Particleboard, ANSI 208, 1

Core/Edge Interface: Stiles and Rails are bonded to core and core assembly is sanded prior to application of crossband and veneer.

Crossband backer for wood veneered doors

Faces: Options include Standard or Custom Wood Veneer minimum 1/50”; Medium Density Overlay or Hardboard; High Pressure Laminate;

Maximum door size: 6-0” wide | 12-0” tall

Thickness options: 1-3/8” | 1-3/4” | 2-1/4”

Fire Ratings: Up to 20 minutes – Meets UL 10B/ 10C & NFPA 252 standards (some restrictions apply)

STC Sound Rating: Up to STC 32

Warranty: Limited Lifetime (see warranty sheet for details)

LEED Options: Recycled Content | No Added Formaldehyde | CARB Phase II

Manufacturing Location: San Antonio, TX USA

Veneer Options: All wood veneers – standard & custom | MDO or Hardboard |

Finishing Options: Unfinished | Primed | Clear Coat | Custom Color Finish (Conversion Varnish)

Specialty Options: Grooves | Raised Moldings | Glass | Exterior | Hardware Machining

Structural Composite Lumber

C-Series Composite Lumber Core 520C/530C

Top and Bottom Rail: 1-1/8” minimum solid wood or structural composite lumber

Vertical Stiles: 3⁄4” thick matching hardwood stile for wood veneer doors; mill option for paint grade doors

Core: Structural Composite Lumber Core, Tested in accordance with WDMA I.S. 10-99

Core/Edge Interface: Stiles and Rails are bonded to core and core assembly is sanded prior to application of crossband and veneer.

Crossband backer for wood veneered doors

Faces: Options include Standard or Custom Wood Veneer minimum 1/50”; Medium Density Overlay or Hardboard; High Pressure Laminate;

Maximum door size: 6-0” wide | 12-0” tall

Thickness options: 1-3/8” | 1-3/4” | 2-1/4”

Fire Ratings: Up to 45 minutes – Meets UL 10B/ 10C & NFPA 252 standards (some restrictions apply)

STC Sound Rating: Up to STC 38

Warranty: Limited Lifetime (see warranty sheet for details)

LEED Options: Recycled Content | No Added Formaldehyde | CARB Phase II

Manufacturing Location: San Antonio, TX USA

Veneer Options: All wood veneers – standard & custom | MDO or Hardboard |

Finishing Options: Unfinished | Primed | Clear Coat | Custom Color Finish (Conversion Varnish)

Specialty Options: Grooves | Raised Moldings | Glass | Exterior | Hardware Machining

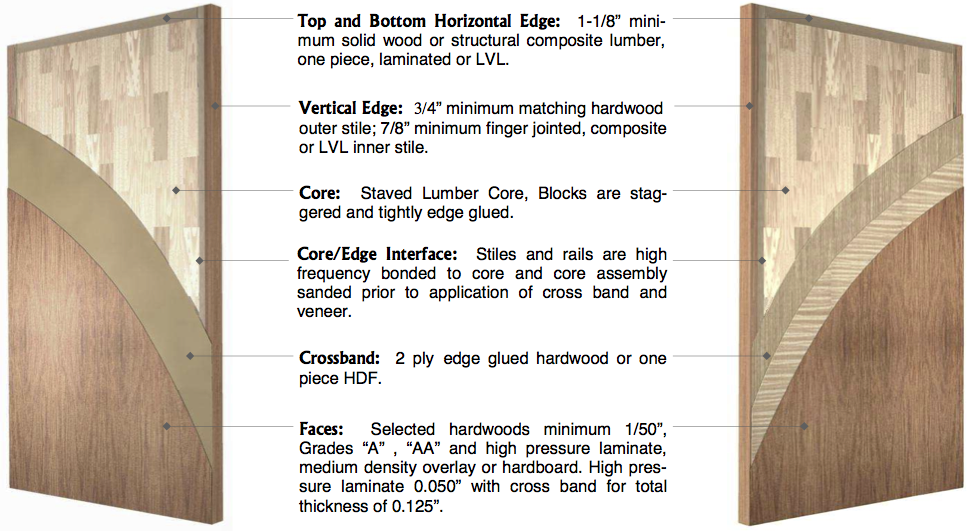

Wood / Stave

S-Series Staved Lumber Core 520S/530S

Solid Core 520S / 530S Staved Lumber Core (SLC) 5 & 7 – Ply

Hardwood Veneer / MDO / HDF or High Pressure Decorative Laminate (HPDL)

WDMA: SLC-5 / SLC-HPDL – Bonded core

AWS: SLC-5 / SLC-HPDL – Bonded core

WDMA: SLC-7 – Bonded core

AWS: SLC-7 – Bonded core

Unless specified otherwise all doors are constructed to Extra Heavy Duty performance levels.

Door sizes: (Non rated) 1-3/8” – 2-1/4” thick, up to 6’ wide x 12’ high (Check with sales for taller doors).

Warranty: Lifetime for interior use / one year limited exterior, fully type 1 wood or MDO faces only. See Vancouver Door Warranty.

Blocking Options: For undercutting and specialized hardware. Must be specified if required. See “Blocking Adds” page

Available Rating Options For 520S

Fire Ratings![]()

- 20 Minute: Neutral Pressure (NP) or Positive Pressure (PP) – Cat “A” or “B” and Intumescent free. Smoke & Draft control label.

-

Max Sizes: NP PP Singles: 4’ x 10’ 4’ x 9’ Std Pairs: 8’ x 10’ 8’ x 9’ Dbl Egress: 8’ x 10’ 8’ x 9’ - Transoms—Up to 4’ x 3’4”

- Vision lites (louvers not allowed)

- Applied Moldings, Quirks & Inlays.

- See the “20 Minute” rating matrix and specificaitons sheet for hardware, frame and other information on ratings

STC Ratings![]()

- Standard construction = STC-28 to STC-32.

- Lites – Recommended glazing systems must be used to obtain the maximum STC rating.

- Pairs or doors with transoms may require additional sealing / gasketing systems.

- “U” value = 0.46 (unglazed). Glazed doors vary based on glazing type. See “Default U factors for doors” matrix.

See the STC Transmission Information.

LEED Credits

- EQ 4.4 – Low Emitting Materials – No Added Urea Formaldehyde (NAUF)

- Low VOC’ s on all finishes.

- All products conform to “CARB” Phase II requirements.

See our “LEED” Matrix for additional information.

Available Construction Options For 520S

- Dutch Door (various shelf types available) See “Dutch shelf options”.

- Wicket Door (Shelf upon request)

- Pairs, Set matches & Bifolds.

- Over-size doors & Splined sets.

- Full or Half louver – Non rated.

- Vision Lites – Various shapes & sizes. Glazed or unglazed.

- Arc or radius top to match jamb.

Sized, beveled & machined for just about any specified surface, concealed or electrified hardware and Prefinished.

Agrifiber

A-Series Agrifiber Core 520A/530A

Solid Core 520A/530A – Agrifiber Core (AC) 3, 5 & 7-Ply

Hardwood Veneer / MDO / HDF or High Pressure Decorative Laminate (HPDL)

WDMA: PC-5 / PC-HPDL 3 or 5 Bonded core

AWS: PC-5 / PC-HPDL 3 or 5 Bonded core

WDMA: PC-7 – Bonded core

AWS: PC-7 – Bonded core

Unless specified otherwise all doors are constructed to Extra Heavy Duty performance levels.

Door sizes: (Non rated) 1-3/8” – 2-1/4” thick, up to 6’ wide x 12’ high (Check with sales for taller doors).

Warranty: Lifetime for interior use / one year limited exterior, fully type 1 wood or MDO faces only. See Vancouver Door Warranty.

Blocking Options: For undercutting and specialized hardware. Must be specified if required. See “Blocking Adds” page

Available Rating Options For 520A

Fire Ratings![]()

- 20 Minute: Neutral Pressure (NP) or Positive Pressure (PP) – Cat “A” or “B” and intumescent free. Smoke & Draft control label.

| Max Sizes: | NP | PP |

| Singles: | 4’ x 10’ | 4’ x 9’ |

| Std Pairs: | 8’ x 10’ | 8’ x 9’ |

| Dbl Egress: | 8’ x 10’ | 8’ x 9’ |

- Transoms—Up to 4’ x 3’4”

- Vision lites (louvers not allowed)

- Applied moldings, Quirks & Inlays.

- See the “20 Minute” rating matrix and specificaitons sheet for hardware, frame and other information on ratings

STC Ratings![]()

- Standard construction = STC-28 to STC-33.

- Lites – Recommended glazing systems must be used to obtain the maximum STC rating.

- Pairs or doors with transoms may require additional sealing / gasketing systems.

- “U” value = 0.46 (unglazed). Glazed doors vary based on glazing type. See “Default U factors for doors” matrix.

See the STC Transmission Information

LEED Credits

- MR 4.1 – Recycled Content: 10%

- MR 4.2 – Recycled Content: 20%

- EQ 4.4 – Low Emitting Materials – No Added Urea Formaldehyde (NAUF)

- Low VOC’ s on all finishes.

- All products conform to “CARB” Phase II requirements.

See our “LEED” Matrix for additional information.

Available Construction Options For 520A

- Dutch Door (various shelf types available) See “Dutch shelf options”.

- Wicket Door (Shelf upon request)

- Pairs, Set matches & Bifolds.

- Over-size doors & Splined sets.

- Full or Half louver – Non rated.

- Vision Lites – Various shapes & sizes. Glazed or unglazed.

- Arc or radius top to match jamb.

Sized, beveled & machined for just about any specified surface, concealed or electrified hardware and Prefinished.

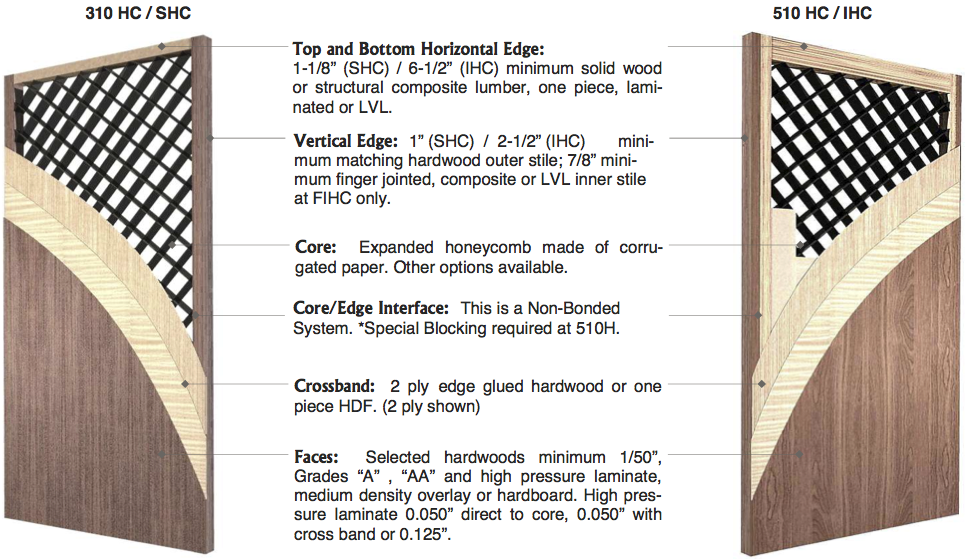

Hollow Core

310 Series – Standard

310H Hollow Core (HC) 5 & 7 – Ply

Hardwood Veneer / MDO / HDF or High Pressure Decorative Laminate (HPDL)

WDMA: SHC / SHC-HPDL 5 or 7

AWS: HC-5 / HC-HPDL 5 or 7

WDMA: SHC 5 or 7

AWS: HC 5 or 7

Door sizes: (Non rated) 1-3/8″ – 2-1/4″ thick, up to 6′ wide x 12′ high (Check with sales for taller doors).

Warranty: One year limited. See Vancouver Door Warranty.

Blocking Options: For undercutting and specialized hardware. Must be specified if required. See “Blocking Adds” page

Available Rating Options For 310H and 510H

Fire Ratings![]()

- None

STC Ratings![]()

- None

LEED Credits

- MR 4.1 – Recycled Content: 10%

- MR 4.2 – Recycled Content: 20%

- Low VOC’ s on all finishes.

- All products conform to “CARB” Phase II requirements.

See our “LEED” Matrix for additional information.

Available Construction Options For 310H and 510H

- Pairs, Set matches & Bifolds.

- Over-size doors & Splined sets.

- Full or Half louver – Non rated.

- Vision Lites – Various shapes & sizes. Glazed or unglazed.

Sized, beveled & machined for just about any specified surface, concealed or electrified hardware and prefinished.

FIRE RATINGS

For 20 minute Ratings

Particleboard Core – 20 minute

Top and Bottom Rail: 1-1/8” minimum solid wood or structural composite lumber

Vertical Stiles: ¾” thick matching hardwood stile for

wood veneer doors; mill option for paint grade doors

Core: Particleboard, ANSI 208, 1

Core/Edge Interface: Stiles and Rails are bonded to core and core assembly is sanded prior to application of crossband and veneer.

Crossband backer for wood veneered doors

Faces: Options include Standard or Custom Wood Veneer minimum 1/50”; Medium Density Overlay or Hardboard; High Pressure Laminate;

Maximum door size: 6-0” wide | 12-0” tall

Thickness options: 1-3/8” | 1-3/4” | 2-1/4”

Fire Ratings: Up to 20 minutes – Meets UL 10B/ 10C & NFPA 252 standards (some restrictions apply)

STC Sound Rating: Up to STC 32

Warranty: Limited Lifetime (see warranty sheet for details)

LEED Options: Recycled Content | No Added Formaldehyde | CARB Phase II

Manufacturing Location: San Antonio, TX USA

Veneer Options: All wood veneers – standard & custom | MDO or Hardboard |

Finishing Options: Unfinished | Primed | Clear Coat | Custom Color Finish (Conversion Varnish)

Specialty Options: Grooves | Raised Moldings | Glass | Exterior | Hardware Machining

SCL – 20 Minute

Top and Bottom Rail: 1-1/8” minimum solid wood or structural composite lumber

Vertical Stiles: 3⁄4” thick matching hardwood stile for wood veneer doors; mill option for paint grade doors

Core: Structural Composite Lumber Core, Tested in accordance with WDMA I.S. 10-99

Core/Edge Interface: Stiles and Rails are bonded to core and core assembly is sanded prior to application of crossband and veneer.

Crossband backer for wood veneered doors

Faces: Options include Standard or Custom Wood Veneer minimum 1/50”; Medium Density Overlay or Hardboard; High Pressure Laminate;

Maximum door size: 6-0” wide | 12-0” tall

Thickness options: 1-3/8” | 1-3/4” | 2-1/4”

Fire Ratings: Up to 45 minutes – Meets UL 10B/ 10C & NFPA 252 standards (some restrictions apply)

STC Sound Rating: Up to STC 38

Warranty: Limited Lifetime (see warranty sheet for details)

LEED Options: Recycled Content | No Added Formaldehyde | CARB Phase II

Manufacturing Location: San Antonio, TX USA

Veneer Options: All wood veneers – standard & custom | MDO or Hardboard |

Finishing Options: Unfinished | Primed | Clear Coat | Custom Color Finish (Conversion Varnish)

Specialty Options: Grooves | Raised Moldings | Glass | Exterior | Hardware Machining

For 45 minute Ratings

SCL CORE

Top and Bottom Rail: 1-1/8” minimum solid wood or structural composite lumber

Vertical Stiles: 3⁄4” thick matching hardwood stile for wood veneer doors; mill option for paint grade doors

Core: Structural Composite Lumber Core, Tested in accordance with WDMA I.S. 10-99

Core/Edge Interface: Stiles and Rails are bonded to core and core assembly is sanded prior to application of crossband and veneer.

Crossband backer for wood veneered doors

Faces: Options include Standard or Custom Wood Veneer minimum 1/50”; Medium Density Overlay or Hardboard; High Pressure Laminate;

Maximum door size: 6-0” wide | 12-0” tall

Thickness options: 1-3/8” | 1-3/4” | 2-1/4”

Fire Ratings: Up to 45 minutes – Meets UL 10B/ 10C & NFPA 252 standards (some restrictions apply)

STC Sound Rating: Up to STC 38

Warranty: Limited Lifetime (see warranty sheet for details)

LEED Options: Recycled Content | No Added Formaldehyde | CARB Phase II

Manufacturing Location: San Antonio, TX USA

Veneer Options: All wood veneers – standard & custom | MDO or Hardboard |

Finishing Options: Unfinished | Primed | Clear Coat | Custom Color Finish (Conversion Varnish)

Specialty Options: Grooves | Raised Moldings | Glass | Exterior | Hardware Machining

745M (3/4 hr) Fire Rated Mineral Core (MC) 5 & 7 – PlY

Hardwood Veneer / MDO / HDF or High Pressure Decorative Laminate (HPDL)

WDMA: FD-45 / FD-45 HPDL 3 or 5 Bonded core

AWS: FD-45 / FD-45 HPDL 3 or 5 Bonded core

WDMA: FD-45 7 – Bonded core

AWS: FD-45 7 – Bonded core

Unless specified otherwise all doors are constructed to Extra Heavy Duty performance levels.

Warranty: Lifetime for interior use only. See Vancouver Door Warranty.

Blocking Options: For undercutting and specialized hardware. Must be specified if required. See “Blocking Adds” page

Available Rating Options For 745M

Fire Ratings![]()

- 45 Minute: Neutral Pressure (NP) or Positive Pressure (PP) – Cat “A” or “B” and Intumescent free. Smoke & Draft control label.

-

Max Sizes: NP PP Singles: 4’ x 10’ 4’ x 9’ Std Pairs: 8’ x 10’ 8’ x 9’ Dbl Egress: 8’ x 10’ 8’ x 9’ - Transoms—Up to 4’ x 3’4”

- Vision lites (louvers not allowed)

- Applied moldings, Quirks & Inlays.

- See the “45 Minute” rating matrix and specificaitons sheet for hardware, frame and other information on ratings

STC Ratings![]()

- Standard construction = STC 35.

- Lites – Recommended glazing systems must be used to obtain the maximum STC rating which may conflict with fire rating requirements.

Currently not tested or approved for pairs or doors with transoms.

See the STC Transmission Information.

LEED Credits

- MR 4.1 – Recycled Content: 10%

- MR 4.2 – Recycled Content: 20%

- EQ 4.4 – Low Emitting Materials – No Added Urea Formaldehyde (NAUF)

- Low VOC’ s on all finishes.

- All products conform to “CARB” Phase II requirements.

See our “LEED” Matrix for additional information.

Available Construction Options For 745M

- Dutch Door (various shelf types available) See “Dutch shelf options”.

- Pairs & Set matches.

- Vision Lites – Various shapes & sizes. Glazed or unglazed.

- Louver – Up to 1296 sqin max.

Sized, beveled & machined for just about any specified surface, concealed or electrified hardware and Prefinished.

For 60 Minute Ratings

760M (1 hr) Fire Rated Mineral Core (MC) 5 & 7 – Ply

Hardwood Veneer / MDO / HDF or High Pressure Decorative Laminate (HPDL)

WDMA: FD-60 / FD-60 HPDL 3 or 5 Bonded core

AWS: FD-60 / FD-60 HPDL 3 or 5 Bonded core

WDMA: FD-60 7 – Bonded core

AWS: FD-60 7 – Bonded core

Unless specified otherwise all doors are constructed to Extra Heavy Duty performance levels.

Warranty: Lifetime for interior use only. See Vancouver Door Warranty.

Blocking Options: For undercutting and specialized hardware. Must be specified if required. See “Blocking Adds” page

Available Rating Options For 760M

Fire Ratings![]()

- 60 Minute: Neutral Pressure (NP) or Positive Pressure (PP) – Cat “A” or “B” and Intumescent free. Smoke & Draft control label.

-

Max Sizes: NP PP Singles: 4’ x 10’ 4’ x 9’ Std Pairs: 8’ x 10’ 8’ x 9’ Dbl Egress: 8’ x 10’ 8’ x 9’ - Transoms—Up to 4’ x 3’4”

- Vision lites (louvers not allowed)

- Applied moldings, Quirks & Inlays.

- See the “60 Minute” rating matrix and specificaitons sheet for hardware, frame and other information on ratings

STC Ratings![]()

- Standard construction = STC 35.

- Lites – Recommended glazing systems must be used to obtain the maximum STC rating which may conflict with fire rating requirements.

Currently not tested or approved for pairs or doors with transoms.

See the STC Methods & Procedure & Voice Level Chart for frequency variables.

LEED Credits

- MR 4.1 – Recycled Content: 10%

- MR 4.2 – Recycled Content: 20%

- EQ 4.4 – Low Emitting Materials – No Added Urea Formaldehyde (NAUF)

- Low VOC’ s on all finishes.

- All products conform to “CARB” Phase II requirements.

See our “LEED” Matrix for additional information.

Available Construction Options For 760M

- Pairs & Set matches.

- Vision Lites – Various shapes & sizes. Glazed or unglazed.

- Louver – Up to 1296 sqin max.

Sized, beveled & machined for just about any specified surface, concealed or electrified hardware and Prefinished.

For 90 Minute Ratings

790M (1-1/2 hr) Fire Rated Mineral Core (MC) 5 & 7 – Ply

Hardwood Veneer / MDO / HDF or High Pressure Decorative Laminate (HPDL)

WDMA: FD-90 / FD-90 HPDL 3 or 5 Bonded core

AWS: FD-90 / FD-90 HPDL 3 or 5 Bonded core

WDMA: FD-90 7 – Bonded core

AWS: FD-90 7 – Bonded core

Unless specified otherwise all doors are constructed to Extra Heavy Duty performance levels.

Warranty: Lifetime for interior use only. See Vancouver Door Warranty.

Blocking Options: For undercutting and specialized hardware. Must be specified if required. See “Blocking Adds” page

Available Rating Options For 790M

Fire Ratings![]()

- 90 Minute: Neutral Pressure (NP) or Positive Pressure (PP) – Cat “A” or “B” and Intumescent free. Smoke & Draft control label.

-

Max Sizes: NP PP Singles: 4’ x 10’ 4’ x 9’ Std Pairs: 8’ x 10’ 8’ x 9’ Dbl Egress: 8’ x 10’ 8’ x 9’ - Transoms—Up to 4’ x 3’4”

- Vision lites (louvers not allowed)

- Applied moldings, Quirks & Inlays.

- See the “90 Minute” rating matrix and specificaitons sheet for hardware, frame and other information on ratings

STC Ratings![]()

- Standard construction = STC 35.

- Lites – Recommended glazing systems must be used to obtain the maximum STC rating which may conflict with fire rating requirements.

Currently not tested or approved for pairs or doors with transoms.

See the STC Transmission Information.

LEED Credits

- MR 4.1 – Recycled Content: 10%

- MR 4.2 – Recycled Content: 20%

- EQ 4.4 – Low Emitting Materials – No Added Urea Formaldehyde (NAUF)

- Low VOC’ s on all finishes.

- All products conform to “CARB” Phase II requirements.

See our “LEED” Matrix for additional information.

Available Construction Options For 790M

- Pairs & Set matches.

- Vision Lites – Various shapes & sizes. Glazed or unglazed.

- Louver – Up to 1296 sqin max.

Sized, beveled & machined for just about any specified surface, concealed or electrified hardware and Prefinished.

SPECIALTY DOORS

Lead -Lined Doors

600 Series Lead Lined (LL) 5 & 7 – Ply

Hardwood Veneer / MDO / HDF or High Pressure Decorative Laminate (HPDL)

WDMA: PC-5 / PC-HPDL 3 or 5 Bonded core

AWS: PC-5 / PC-HPDL 3 or 5 Bonded core

WDMA: PC-7 – Bonded core

AWS: PC-7 – Bonded core

Unless specified otherwise all doors are constructed to Extra Heavy Duty performance levels.

Warranty: Lifetime for interior use only. See Vancouver Door Warranty.

Blocking Options: For undercutting and specialized hardware. Must be specified if required. See “Blocking Adds” page

Available rating options for 600 LL

Fire Ratings![]()

- 20 Minute: Neutral Pressure (NP) or Positive Pressure (PP) – Cat “A” or “B” and intumescent free. Smoke & Draft control label.

-

Max Sizes: NPPPSingles: 4’ x 10’4’ x 9’Std Pairs: N/AN/ADbl Egress: N/A’N/A - Transoms—Up to 4’ x 3’4”

- Vision lites (louvers not allowed)

- Applied moldings, Quirks & Inlays.

- See the “20 Minute” rating matrix and specificaitons sheet for hardware, frame and other information on ratings

STC Ratings![]()

- Standard construction = STC 37.

- Lites – Recommended glazing systems must be used to obtain the maximum STC rating which may conflict with fire rating requirements.

Currently not tested or approved for pairs. Pairs or doors with transoms may require additional sealing / gasketing systems.

See the STC Transmission Information.

LEED credits

- MR 4.1 – Recycled Content: 10%

- MR 4.2 – Recycled Content: 20%

- EQ 4.4 – Low Emitting Materials – No Added Urea Formaldehyde (NAUF)

- Low VOC’ s on all finishes.

- All products conform to “CARB” Phase II requirements.

See our “LEED” Matrix for additional information.

Sized, beveled & machined for just about any specified surface, concealed or electrified hardware and Prefinished.

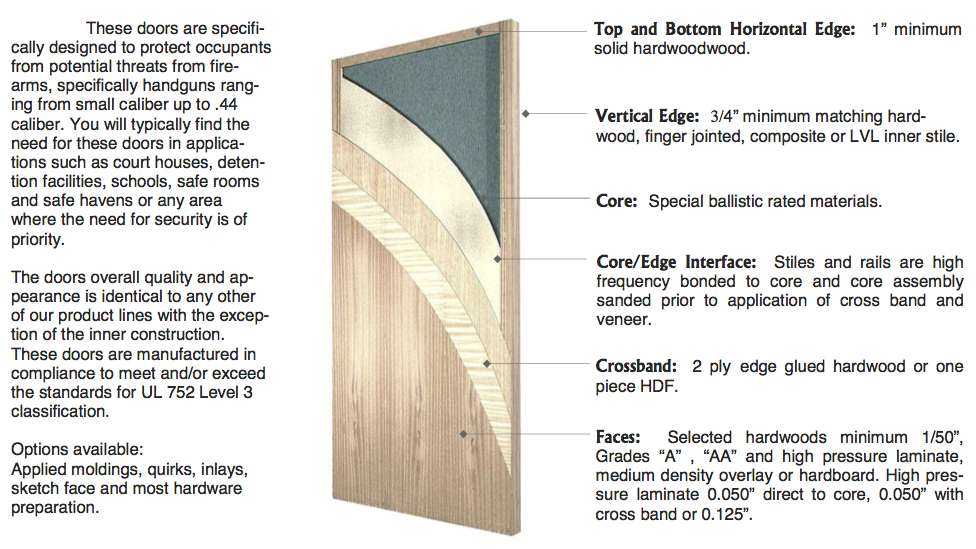

Bullet-Resistance Doors

650 Series Bullet Resistant 5 & 7 – Ply

Hardwood Veneer / MDO / HDF or High Pressure Decorative Laminate (HPDL)

WDMA/AWS: BR – Special Function Doors

Door sizes: (Non rated) 1-3/4” – 2-1/4” thick, up to 4’ wide x 8’ high (Check with sales for larger doors).

Warranty: Lifetime for interior use only. See Vancouver Door Warranty.

Blocking Options: For undercutting and specialized hardware. Must be specified if required. See “Blocking Adds” page

Available rating options for 650

Fire Ratings![]()

- N/A

STC Ratings![]()

- Standard construction = STC 37.

- Lites – Recommended glazing systems must be used to obtain the maximum STC rating which may conflict with fire rating requirements.

Currently not tested or approved for pairs. Pairs or doors with transoms may require additional sealing / gasketing systems.

See the STC Transmission Information.

LEED credits

- MR 4.1 – Recycled Content: 10%

- MR 4.2 – Recycled Content: 20%

- EQ 4.4 – Low Emitting Materials – No Added Urea Formaldehyde (NAUF)

- Low VOC’ s on all finishes.

- All products conform to “CARB” Phase II requirements.

See our “LEED” Matrix for additional information.

*Note: Each STC rated door requires a specific sealing system to maintain the rating. We can supply a complete system or you may supply as long as the system conforms to the test data. Check with our technical department.

Sized, beveled & machined for just about any specified surface, mortised or electrified hardware and Prefinished.

These doors are specifically designed to protect occupants

from potential threats from fire- arms, specifically handguns rang- ing from small caliber up to .44 caliber. You will typically find the need for these doors in applications such as court houses, deten- tion facilities, schools, safe rooms and safe havens or any area where the need for security is of priority.

The doors overall quality and appearance is identical to any other of our product lines with the exception of the inner construction. These doors are manufactured in compliance to meet and/or exceed the standards for UL 752 Level 3 classification.

Options available:

Applied moldings, quirks, inlays, sketch face and most hardware preparation.

Sound-Rated Doors

800 Series Acoustical (STC) Door 5 & 7 – Ply

Hardwood Veneer / MDO / HDF or High Pressure Decorative Laminate (HPDL)

WDMA/AWS: BR – Special Function Doors – STC-36, 39, 40, 42, or 43

Door sizes: (Non rated) 1-3/4” – 2-1/4” thick, up to 4’ wide x 8’ high (Check with sales for larger doors).

Warranty: 5 Year for interior use only. See Vancouver Door Warranty.

Blocking Options: For undercutting and specialized hardware. Must be specified if required.

See “Blocking Adds” page

Available Rating Options For 800 STC

Fire Ratings![]()

- N/A

STC Ratings![]()

- Levels vary from STC-36 to STC-43

- Lites – Recommended glazing systems must be used to obtain the maximum STC rating which may conflict with fire rating requirements.

Currently not tested or approved for pairs or doors with transoms.

See the STC Transmission Information.

LEED Credits

- MR 4.1 – Recycled Content: 10%

- MR 4.2 – Recycled Content: 20%

- EQ 4.4 – Low Emitting Materials – No Added Urea Formaldehyde (NAUF)

- Low VOC’ s on all finishes.

- All products conform to “CARB” Phase II requirements.

See our “LEED” Matrix for additional information.

*Note: Each STC rated door requires a specific sealing system to maintain the rating. We can supply a complete system or you may supply as long as the system conforms to the test data. Check with our technical department.

Sized, beveled & machined for just about any specified surface, mortised or electrified hardware and Prefinished.

Acoustical or Sound Resistant doors are tested in accordance with ASTM E90, E413 & E1332. The operable tests give the result s of Sound Transmission Loss and the determination of the Sound Transmission Class (STC) for door systems.

These doors can be specified for a number of applications where noise reduction is required. Typical applications for this type of door are: Meeting or classrooms, band rooms, auditoriums, hotel rooms, etc.

More information can be obtained on the “Sound transmission infor- mation” section of our website.

Options available

Applied molding, overlays, sketch face and hardware machining.

Transom Panel

DOORS & TRANSOMS

Veneers may be continuous match, end

match or no match. (Continuous matched shown)

See WDMA: I.S. 1-A, Section A-7

Rabetted meeting rails are optional.

Not approved for STC applications.

Available non-rated and 20, 45, 60, and 90 minute rated. See pages 9 & 10

Check with our sales or tech department for details & options.

Transom Door

Dutch Doors

DUTCH DOORS

Dutch doors are utilized in applications where the upper half

of the door may be opened while keeping the lower half closed.

Both leaves are typically latched together to maintain a single opening.

Dutch door shelves on one side only or on both sides of the door. All shelves are sent loose for field installation.

Available non-rated and 20, 45 minute rated.

Check with our sales or tech department for details & options.

Dutch Door

Dutch Door

Applied Mouldings

Applied Moldings For Doors

Applied moldings or “Plant-ons” can be produced in any number of configurations and with any number species. Molding can be supplied to match the face species or can be mixed as shown in the door samples below. There are several types of molding profiles available that can be provided to match new or existing conditions. Molding can be applied to just about all of our products but there are some considerations that must be met on fire rated doors. Please check with our sales or technical department.

The following examples are just a sample of the possibilities that can be achieved with applied molding.

Standard Molding Configuration Examples

Standard Molding Profiles

Grooved Doors, Inlays, Sketch Face Doors

Inlays, Sketch Face and Quirks

There are a multitude of options available for designer doors that can be configured in unlimited combinations to meet the desired appearance. Our goal is to produce an aesthetically appealing door but to also maintain the integrity in the construction that assures your door will last for a long time. Most of these doors can be produced in accordance with most fire rating and LEED applications but depending on the materials being used there may be restrictions.

The following examples are just a sample of the possibilities that can be achieved in producing a designer door to specification.

Inlays

Inlays can be produced in many configurations with various materials such as wood, metal and/or laminates.

Sketch Face

Sketch face doors are produced when veneers are laid out in a specific pattern on the skin backer. The veneers can be book, slip or random match and can be mixed with different species for the perfect contrast.

Quirks

Quirks (grooves) are cut into the face in any symmetrical, non symmetrical circular, straight or diagonal pattern.

Glass and Vision Lites

Vision Lites, Stops and Glazing

Vision lites can be provided in all of our products in just about any shape, size or configuration required, from small, narrow, half, full, square, rectangular, round or oval. Combinations of lites may also be provided granted the overall area does not exceed the maximum allowed area for warranty or fire rating restrictions (Please check with our sales or technical department for limitations). Both wood and metal vision stop can be supplied upon request. We can also provide factory glazing.

Below are just some examples of vision lites utilizing our typical stop.

Small Lites

Small vision lites can be of various geometric shapes and are typically provided in single or multiple layouts.

Narrow Lites

Narrow vision lites are common for many applications that require a larger area of vision than small lites but do not remove asmuch of the door material as half or full lite doors. The dimension from vision lite to edge of door or lock prep must not exceed 5” for warranty or fire ratings.

Half and Full Lites

Half and Full vision lites allow for optimal openings in the door. Full vision lites give the highest level of light through and/or visible clearance. To maintain the entegrity and warranty Structural Composite Lumber Core (SCLC) must be used on all doors that are to receive full lites.

We supply two types of wood bead stop (shown on the left) in various species to match face. There are other profiles available through special request and can be utilized for different thicknesses of glass. The type of vision kit supplied will depend on the type of product it is to be used with. IE: only the VS-230 Lip Stop can be used for 20 minute fire rated doors and for HPDL doors.

Metal vision kits can be supplied for other products like 45, 60 & 90 minute rated doors that have different glazing requirements or where security is an issue.

The picture below shows the installation of glazing in a 20 minute rated door.

Louver Door inserts

LOUVERS – 45-90 MINUTE FLUSH DOOR NEUTRAL PRESSURE

Listed and labeled fusible link louvers are allowed.

Louvers shall be located a minimum of 10″ (254 mm) from the bottom of the door and 5″ (152.4 mm) from the edge of the door or any other cutout.

Multiple louvers are allowed (within the maximum area stated below).

Maximum area: 1296 square inches (0.836 square meters)

Maximum width: 24″ (609 mm)

Maximum length: 24″ (609 mm)

Note: Doors prepared for louvers shall not have fire exit hardware or vision panels installed (per NFPA 80).

Reinforced Blocking

VENEERS OPTIONS

Veneer Cuts

|

Rotary Cut The log is centered mounted in a lathe and rotated at a high rpm as the blade is slowly move in to peel a thin layer of wood from the log. This slice follows the log’s annular growth rings, a general bold variegated and random appearance is produced. Once the sheets have been produced or lathed from the log, they can be spliced to the desired flitch dimensions. This is probably the least expensive cut due to the yield. |

|

|

Plain Sliced (Flat Cut) The half log is mounted with the heart side floating against the guide plate of the slicer, and the slicing is done parallel to a line through the center of the log, producing a variegated figure. This cut produces a grain pattern in the shape of an inverted “V” or what is commonly referred to as a cathedral or crown pattern. Plain slicing may also produce a rotary cut appearance, a quartered cut appearance or even a rift cut appearance depending on the individual log and angle of the slicing of that log. |

|

|

Quarter Slicing The quarter log is mounted on the guide plate so that the growth rings of the log strike at approximately right angles, producing a very straight grain (quartered) in some woods and varied grain appearance in other woods. In both red and white Oak, this slicing can produce unlimited amounts of medullary rayor ray fleck. Although these rays can not be totally eliminated in straight grain cuts it can be minimized by rift cutting the quarter of a log. |

|

|

Rift Cut / Comb Grain (Red & White Oak ONLY!) The Rift or Comb grain effect is produced by slicing perpendicular to the Oak’s medullary rays on either the lathe or the slicer. This particular cut produces a very distinguishable straight and tight grain over the length of the entire flitch. This also minimizes the medullary rays that are produced in quarter cut veneers. Further more it is a better cut for matching adjacent flitches as well as stock or lumber material. Comb grain is the “hybrid “to Rift cut as far as tightness of grain and absence of rays or flecks. |

|

Veneer Matching

Veneer Matching – Individual Veneer Pieces

Once the veneer has been cut from the log as described in the “Veneer Cuts” page it must be determined and specified as to how the flitches are to be spliced together next to one another to form a panels face. Veneer jointing is the first step in matching two flitches to be spliced together. This is where the specified grade and flitch width will be established for each adjoining flitch. Once the veneer has been jointed it will need to have the edges glued and the veneer is ready for splicing. There are two basic methods of achieving this and the majority of today’s veneering is computer processed but there are still some that perform this operation manually. If no match is specified than by default Book Match is used as this match is the most commonly used match for “A” grade.

Below are examples of the most common matches for architectural grade veneers. Some of the other optional matches include Color and Pleasing match (grain is not required) and Plank matching (Deliberately produces a random appearance).

BOOK MATCH

This is by far the most common match. This is achieved by turning over every other veneer component from its sequence in the pile and edge gluing it to the previous flitch from the pile. It is essentially creating a mirror image of the flitch next to it. Although this type of matching is the most pleasing it also produces an effect that is called the “Barber Pole” effect. This is the cause of turning over every other flitch which puts the “Tight side” of one flitch facing outward and the “Loose side” of the adjacent flitch facing outward. This may refract light differently between the side by side flitches emitting a color or contrast variation. On a typical panel you may have several flitches over the entire face and this can be an undesirable effect for some.

SLIP MATCH

This method is achieved by pulling a flitch in sequence and placing it next to the previous flitch with out flipping it over. This puts the pattern on the opposite side but keeps the tight-side outward on all panels so as not to produce the “Barber Pole” effect. Some find this match as a alternate in eliminating the “Barber pole” effect but it also has some undesirable issues. One of these is that it produces a sharp contrast between the two flitches which is allowed in most standards due to the yield required to eliminate this completely. Another issue is the leaning effect this can cause when the grain slope over particularly larger doors make it appear to have a lean or twist to one side.

RANDOM MATCH

No sequencial match is required for this match. Flitches are placed out of order and may not even be from the same log. The goal of this match is to produce an un-matched and random appearance in both color and grain.

Pair or set matching is not an option for a random matched face.

Veneer Assembly

Assembly of Veneer Flitches on Faces

The assembly refers to how the specified matched veneer flitches as outlined on the “Veneer Matching” page are to be assembled across the given panel or door width. Some of the particular matches across the a given door width will determine flitch sizes and associated costs due to the yield that some require from the log. It must also be noted that there is a nominal minimum flitch width for both premium (“AA”) and custom (“A”) grade product and it does vary between the different veneer cuts.

If no match is specified than by default “Running Match” will be utilized as this is the most common type for “A” grade doors. If sequence or blue print matching are required it must be specified as some suppliers may only match up to a certain amount of panels due to the yield from the log.

Shown below are the three basic matches that are specified for architectural doors.

RUNNING MATCH

This match is the standard or default if no other match is specified for custom (“A”) grade faces. This is also the most economical of all the matches as it can be produced from larger flitches of un-equal width. In most cases the outer edges of the final trimmed panel or face will be narrower than the inner flitches. It is strongly recommended that this match not be specified when sequential matching from door to door is required.

BALANCE MATCH

Each face is assembled from flitches of equal width. It may contain an equal or odd number of flitches within the trimmed panel or face. An odd number of flitches will result in the outer flitch from one edge to the next to be oriented in a different direction on book matched faces.

Only at the outer edges will the flitch width differ by up to a maximum of one inch as allowed by standards.

CENTER BALANCE MATCH

This match requires that there be an equal number of flitches of equal width. This places a joint in the middle of the trimmed panel. The outer panels may be reduced after trim up to 1” on custom (“A”) grade and 1/2” of premium (“AA”) grade panels. The exact allowance on the offset of the center joint is 1/4” to 3/8”. The yield factor for this particular match is somewhat higher and therefore the cost is augmented particularly on some species if available.

SLIP CENTER BALANCE MATCH

Quarter and rift (comb) cuts are generally specified for this type of match. The panel is comprised of equal sized flitches with a center joint where the two center flitches are book matched and the direction is mirrored from the opposite side for the balance of the panel. All other aspects apply to “center balance” match.

Pair, Set and End Matching

STANDARD And DOUBLE EGRESS PAIRS

Both leaves are of

equal width or 1/2 of

the nominal opening.

UN-EQUAL PAIRS

The active leaf is larger than the in- active leaf.

SET MATCHES

END MATCH

The doors and panels are made with the same matching faces and the panel is rotated 180 degrees to match the top of the door with the patterns mirrored. This is typically used for custom but can be used at premium grade as well.

Note: A slight misalignment may occur between panels which is allowed. Maxi- mum is 3/8” on singles and 1/2” on pairs.

CONTINUOUS MATCH

The doors and panels are made with the same matching faces, in most cases the assemble face is supplied long enough to account both the length of door and transom. The final result is a continuous grain match from the top to the transom or panel to the bottom of the door. This is typically used for premium grade.

Note: A slight misalignment may occur between panels which is allowed. Maximum is 3/8” on singles and 1/2” on pairs.

Veneer Selection

Hardwood Veneer / MDO / HDF / High Pressure Decorative Laminate HPDL

There are a multitude of choices when it comes to selecting the face of a door to address the aesthetics desired for any particular project. Along with the performance criteria there are also criteria for the appearance of a door which is clearly defined by industry standards that all follow the Hardwood Plywood Veneer Association (HPVA) guidelines.

Doors will in most cases have what is referred to as a backer, sub-straight or platform that is glued to the actual face material and then glued to the door core construction. The backer is typically a one piece HDF or two piece edge glued plywood that adds stability and strength to the face and also eliminates possible telegraphing of the core components. Veneer by standards is usually 1/50 of an inch thick.

There are three main classifications or grades when it comes to veneering options.

- PREMIUM GRADE (AA GRADE): Typically specified for projects that seek the highest level of quality and workmanship. Premium grade veneers can also come with a premium price.

- CUSTOM GRADE (A GRADE): Specified for high quality workmanship. This is typically the standard when specifying veneers.

- ECONOMY GRADE (B GRADE): Seldom specified for architectural projects.

*If no grade is specified than custom grade is the default.

Veneers for Transparent Finishes.For these door faces the following is required to be specified.

- Specie. There are numerous foreign and domestic species available. It is highly recommended to check with the supplier to ensure the specie is in fact available.

- Cut. This is the appearance of individual pieces of veneer and how they are cut or spliced from a log. More information can be obtained in the “Veneer Cuts” page.

- Matching. This determines how the individual pieces are placed adjacent to each other on the face. More information can be obtained on our “Veneer Matching” page.

- Assembly. This determines how the veneer flitches will be assembled on the face.

More information can be obtained on our “Veneer Assembly” page.

There are several publications available that cover many veneering options, specific specie description and attributes to help on this subject.

Materials for Opaque Finishes.

- Medium Density Overlay (MDO), Medium Density Fiberboard (MDF), or hardboard (HDF). These types of materials provide the best option for achieving a finely smooth and less porous surface for painting.

Laminates

- High Pressure Decorative Laminates (HPDL): We offer several colors and finishes from all the laminate manufacturers worldwide. Edges of the doors can be laminated to match, painted or stained. High gloss laminates should be avoided because they tend to accentuate natural telegraphing of door components.

Please see our “Other Face Options” page to obtain more information on these and other products that are available. If there is no reference to a specific material, please contact us.

Laminate & Opaque

There are options available used in lieu of veneering for door faces. As with veneered faces these types of products must also be specified in addition to the construction method.

High Pressure Decorative Laminate (HPDL)

This product can be supplied in a multitude of colors, patterns and textures from a number of manufacturers. The laminate itself must meet the National Electrical Manufacturers Association (NEMA) standards of LD-3 latest edition which covers the minimum grade for this application. Typically the laminate itself can be pressed directly to the core assembly creating a 3-ply construction or it can be pressed to a backer on the core assembly creating a 5-ply assembly. Depending on the product type the laminate is to be pressed on will dictate what ply construction will be used. Door vertical edges can be laminated with the same material as face. The preferred method is to apply the edges after faces to make any replacement of the edge possible. When applied before the face it makes replacement very difficult.

Opaque Facing Materials

Medium Density Overlay (MDO)

This is a thin but very rigid condensed paper product that is utilized as a premium grade product. Typically MDO is applied to an HDF backer and then to door core assembly creating a very durable and smooth surface that can be painted.

High Density Fiberboard (HDF) / Medium Density Fiberboard (MDF)

HDF and MDF material can be utilized as well for a custom grade face for an opaque finish. Both products comply to their respective ANSI standards for this type of product.

A sound closed grain hardwood veneer such as Paint Grade Birch may also be used as a custom grade facing option for opaque finishing.